OEM/ODM Metal Parts 2.0 for Computer and Mechanical Components: CNC Machining and Medical Components

Zhilei Energytech Co.,Ltd., a Taiwan-based company, is at the forefront of innovative metal parts manufacturing. The company specializes in CNC machining, computer components, and mechanical parts that are used in various industries. They have successfully satisfied different needs of their clients in the medical, automotive, aerospace, and consumer goods industries, among others.In their commitment to providing personalized quality services and products, Zhilei Energytech offers original equipment manufacturing (OEM) and original design manufacturing (ODM) services to their clients. This means that Zhilei Energytech can produce the required products under the client's name or develop a product from scratch guided by the client's specifications. Zhilei Energytech ensures that client satisfaction is a top priority. Therefore, they have taken the necessary steps in ensuring that their products and services remain of high quality and in line with the industry standards. They have put in place a quality management system that is certified by ISO 9001:2015. This certification is a testament to the company's commitment to manufacturing high-quality products that meet their clients' needs' quality and reliability requirements and adheres to the required standards.The company's metal processing technique utilizes the latest technology in CNC machining. Experts with vast experience in manufacturing metal parts apply computer-aided design (CAD) and computer-aided manufacturing (CAM) processes. The company invests in the latest machinery that ensures that their products conform to the highest quality and have precision. This investment in technology and equipment translates to products that have short manufacturing cycles, outstanding quality, and efficient production speeds.Zhilei Energytech has a team of experienced engineers who work with their clients to achieve specific and intricate product requirements. The team offers expertise in design, prototyping, testing, and analysis to ensure that the final product meets the client's exact requirements. The team can produce components ranging from simple parts to complex parts with a high degree of accuracy.Zhilei Energytech has diverse capabilities in manufacturing CNC machined parts, computer components, and mechanical parts that can be used in various industries. Some of the industries that benefit from the company's services include Aerospace and Defense, Medical Devices, Communication, and Industrial Automation. In the medical industry, the company specializes in producing essential components that are used in various medical devices. The components require high precision and accuracy, and Zhilei Energytech has the expertise to manufacture them to meet the high standards required in the medical industry.Zhilei Energytech has invested in research and development to ensure that they remain at the forefront of innovation in their manufacturing processes. The company continues to collaborate with its clients and provide bespoke services that satisfy their clients' needs. They understand that innovation is key to staying competitive, and Zhilei Energytech ensures a high level of investment in this field.In conclusion, Zhilei Energytech Co.,Ltd. is a leader in original equipment manufacturing (OEM) and original design manufacturing (ODM) services for computer components and mechanical parts. They offer a unique set of services that are of high quality and meet industry standards. The company prides itself on maintaining a high level of client satisfaction by offering personalized services that meet their clients' exact requirements. They continue to invest in innovation and technology to remain competitive and provide high-quality services to their clients. The company is a reliable and trusted partner for those in the aerospace and defense, industrial automation, communication, and medical devices industries, among others.

Read More

Boost Productivity and Precision: CNC Machining Solutions for Aerospace Parts

Title: Innovating the Aerospace Industry: Cutting-Edge CNC Machining of Precision PartsIntroduction:In the fast-paced world of aerospace manufacturing, precision and efficiency are key to success. From commercial airlines to space exploration, every component plays a vital role in ensuring the safety and performance of aircraft. To meet the rigorous demands of this industry, a leading company in CNC machining (need to remove brand name) has revolutionized the manufacturing process of aerospace parts. With their cutting-edge technology and commitment to excellence, they are pushing the boundaries of innovation and reinforcing their position as an industry leader.Revolutionizing the Manufacturing Process:Traditional manufacturing techniques have given way to advanced CNC machining, enabling higher precision, increased production rates, and reduced costs. By harnessing the power of computer-controlled systems and automation, the company (need to remove brand name) has introduced a new era of aerospace part production.The sophisticated CNC machines can accurately mold even the most complex shapes and geometries required in aerospace components. This millimeter-level precision ensures optimal fit, performance, and compatibility, while maintaining strict adherence to safety standards and regulations.Furthermore, the automation and streamlined operations of CNC machining enable faster production rates and significantly reduce the risk of human error. Time-intensive tasks, such as drilling, milling, and turning, are performed with unparalleled precision and speed, allowing for increased productivity and shorter lead times.Pushing the Boundaries of Innovation:The company's commitment to innovation is evident in their continuous investment in research and development. They work closely with aerospace engineers and industry experts to identify emerging needs and develop state-of-the-art machining solutions.One area of focus is lightweighting. With fuel efficiency at the forefront of the aerospace industry, there is a constant drive to reduce the weight of aircraft components. The team at (remove brand name) utilizes cutting-edge materials and advanced machining techniques to create lightweight yet durable parts. This not only improves fuel efficiency but also enhances overall flight performance.Additionally, the company places a strong emphasis on sustainability. They adopt green manufacturing practices, ensuring minimal waste generation and efficient resource utilization. By employing CNC precision machining, they are able to produce accurate and precise parts, minimizing material waste and reducing environmental impact.Quality Assurance:Quality assurance is of paramount importance in aerospace manufacturing, and (remove brand name) understands this crucial aspect. They have implemented robust quality control measures at every stage of the manufacturing process, from design to final inspection.Advanced metrology tools and techniques are employed to perform comprehensive dimensional inspections, verifying the accuracy and consistency of each part. Additionally, the company complies with industry-specific standards and certifications, ensuring that their products meet the highest levels of safety and performance.Partnerships and Future Prospects:The company's commitment to excellence has earned them recognition and trust from major players in the aerospace industry. Their partnerships with leading aerospace manufacturers have provided them with invaluable insights and opportunities to continually improve their machining capabilities.Looking toward the future, (remove brand name) aims to further expand their expertise and offer innovative solutions to upcoming aerospace challenges. With ongoing investments in research and technology, they strive to stay at the forefront of the ever-evolving aerospace industry.Conclusion:Through cutting-edge CNC machining, (remove brand name) has revolutionized the aerospace manufacturing landscape. By harnessing the power of precision and technology, they have set new benchmarks in producing aerospace parts with superior quality, efficiency, and reliability. With their commitment to innovation and dedication to customer satisfaction, they are poised to shape the future of aerospace manufacturing.

Read More

CNC Machining & Prototyping Services for Metal and Plastic Materials

Precision machining plays a critical role in various industries, including aerospace, automotive, medical, and manufacturing. CNC machining services have become a popular choice for businesses because of their high accuracy and efficiency in producing complex parts and components. And as the demand for precision machining continues to grow, CNC machining service providers like {need to remove brand name} have stepped up their game to deliver exceptional services to clients across different industries.{CNC custom machining part} is a CNC machining service provider that specializes in CNC precision machining and rapid prototyping. The company has built a reputation for delivering high-quality products and excellent customer service. For over a decade, {company name} has been providing CNC machining services to companies from different industries, including aerospace, medical, automotive, and telecommunications.What makes {company name} stand out from other CNC machining service providers is its commitment to providing the best quality products and services to clients. The company takes pride in having state-of-the-art equipment and a team of highly skilled and experienced engineers and machinists who understand the complexities of CNC machining. The team at {company name} is dedicated to delivering accurate and high-quality components while maintaining a fast turnaround time.The CNC machining services offered by {company name} cover a wide range of materials, including both metal and plastic. They can produce prototypes, low-volume runs, and high-volume production parts. With their highly accurate CNC machines, they can produce precision parts with tolerances as tight as ±0.005mm. Their CNC machines are capable of handling a wide range of part sizes, from small components to large-scale parts.One of the primary advantages of {company name}'s CNC machining services is their ability to produce parts with high accuracy and repeatability. Instead of relying on manual labor, their CNC machines use computer programs to control the machining process, ensuring that each part is produced to the exact same specifications. This consistency is crucial for industries like aerospace and medical, where precision is essential in ensuring the safety and reliability of the components.In addition to their precision machining services, {company name} also offers rapid prototyping services. Rapid prototyping is an excellent way for businesses to test their designs and make modifications before moving to full-scale production. With {company name}'s rapid prototyping services, clients can have their parts produced quickly, allowing them to test and make alterations to their design efficiently.{company name} is committed to providing the best customer service in the industry. They understand that each client has unique needs and work closely with them to design, manufacture, and deliver custom parts and components that meet their exact requirements. Their team of engineers and machinists is on hand to provide expert advice and guidance throughout the entire process.In conclusion, {company name} is a CNC machining service provider that offers exceptional services to clients across different industries. With their state-of-the-art equipment and experienced team, they can produce high-quality parts and components with precision and accuracy. Their commitment to customer service and fast turnaround times makes them a reliable partner for businesses looking to produce custom parts. To learn more about their CNC machining services or to get a quote, visit their website.

Read More

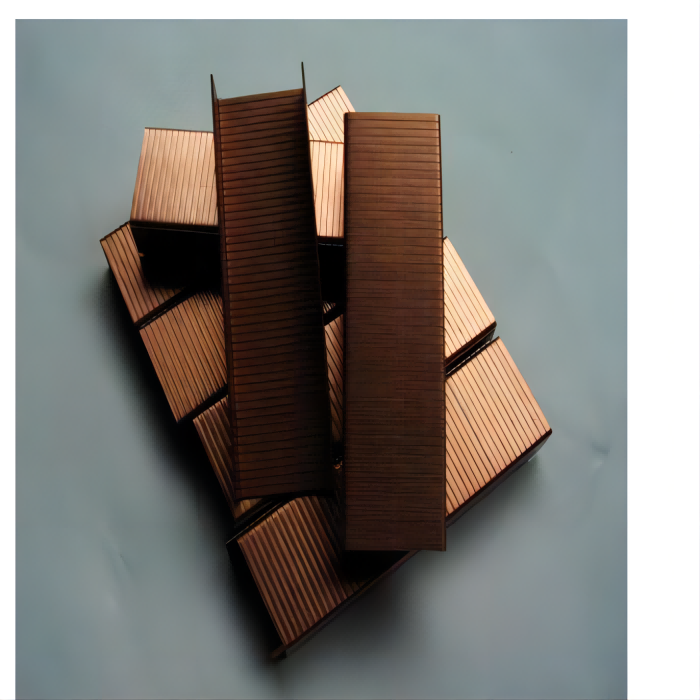

Discover the Advantages of Using Fine Wire Staples for Your Project - Top 10 Benefits of 53/10 Staples

Article:Stapling is an essential task in various industries, from packaging to construction and everything in between. One of the most commonly used staples is the 53/10 fine wire staple, a thin yet sturdy fastener that can join materials with precision and reliability. With its sleek design and wide range of applications, the 53/10 staple has become a staple (no pun intended) in many workplaces and households.One company that has specialized in producing and distributing 53/10 fine wire staples is (brand or company name). Since its inception, (company name) has been committed to providing high-quality staples that meet the needs and expectations of its customers. The company's mission is to deliver staples that offer superior performance, durability, and affordability, while also reducing environmental impact and promoting sustainability.One of the advantages of using 53/10 fine wire staples is their versatility. These staples can be used with various staplers and stapling machines, including manual, electric, and pneumatic models. They are also compatible with a wide range of materials, such as paper, cardboard, fabric, leather, plastics, and even wood. This makes 53/10 fine wire staples an ideal choice for various applications, including crafting, upholstery, carpeting, furniture, and more.Another feature that sets 53/10 fine wire staples apart is their strength and precision. These staples are made of high-quality materials that can withstand tension, pressure, and bending without breaking or deforming. Their narrow profile allows them to penetrate materials without causing damage, ensuring a neat and clean finish. Additionally, 53/10 fine wire staples come in different lengths, allowing users to choose the right size for their specific needs.One of the challenges that (company name) has faced is the competition from other staple brands and suppliers. However, the company has managed to stay ahead of the game by staying up-to-date with the latest technologies and trends in the staple industry. (Company name) has invested heavily in research and development, testing new materials, manufacturing processes, and staple designs to improve its products' quality and performance continually.Besides, (company name) has also implemented environmentally friendly practices in its operations, such as using recycled materials and reducing waste and energy consumption. The company also educates its customers on the importance of sustainable and responsible stapling practices, such as avoiding overuse of staples, recycling used staples, and choosing staplers and staples with eco-friendly certifications.In conclusion, the 53/10 fine wire staple is a versatile, reliable, and durable fastener that has become a staple in many industries and households. (Company name) is one of the leading suppliers of 53/10 fine wire staples, offering high-quality products that meet the needs and expectations of its customers. The company is committed to continuous improvement, innovation, and sustainability, making it a preferred choice for those who value quality, performance, and responsibility. Whether you're a DIY enthusiast, a professional craftsman, or a business owner, you can count on (company name) to provide you with the best 53/10 fine wire staples on the market.

Read More

Understanding the Factors Influencing the Performance of a Trending Stock

: To improve your SEO ranking, include keywords throughout your blog post, particularly in page titles, headings, and meta descriptions.Astronics Corporation (ATRO) is a company that provides specialized technology solutions for industries such as aerospace, defense, and transportation. With their recent inclusion on Zacks.com's list of the most searched stocks, it's worth taking a closer look at what might be driving their popularity, and whether or not this trend is likely to continue.One potential reason behind ATRO's popularity is the fact that they are a leader in the field of technology solutions for the aerospace industry. As the world becomes increasingly reliant on air travel, the demand for cutting-edge technology to support this industry is only likely to grow. In particular, ATRO has expertise in areas such as aircraft lighting, power systems, and advanced testing equipment, all of which are critical components for ensuring the safety and efficiency of aerospace operations.Another factor that may be driving interest in ATRO is their recent financial performance. In the past year, the company has seen steady revenue growth and has outperformed analyst expectations in terms of earnings per share. Additionally, their balance sheet appears strong, with healthy operating cash flow and relatively low debt levels.Of course, as with any stock, there are also potential risks to consider when evaluating the potential performance of ATRO. For example, the aerospace industry is notoriously cyclical and can be impacted by external factors such as global economic conditions or geopolitical tensions. Additionally, ATRO faces competition from other technology providers in their field, which could impact their ability to maintain market share and profitability over the long term.Despite these potential risks, there are reasons to be optimistic about the future prospects of ATRO. The company has a strong track record of innovation and has demonstrated an ability to stay ahead of emerging trends in their industry. They also have a diversified customer base, with relationships with major players in both the commercial and military aerospace markets.Ultimately, whether or not ATRO is a good investment opportunity depends on a variety of factors, including your personal risk tolerance, investment goals, and overall portfolio strategy. However, by considering the trends that are driving interest in the company, as well as the potential risks and opportunities that exist in their industry, you can make a more informed decision about whether or not to add ATRO to your portfolio.

Read More

Discover the Latest Trends in Custom Sheet Metal Stamping: An In-Depth Analysis

Custom Sheet Metal Stamping Revolutionizing Manufacturing ProcessesThe manufacturing industry has evolved significantly over the years, with companies relentlessly searching for solutions that enhance efficiency, reduce costs, and ultimately, are capable of catering to specific customer needs. One method rapidly gaining traction in this pursuit is custom sheet metal stamping, revolutionizing the manufacturing and fabrication processes across various industries.Custom sheet metal stamping is a process that involves shaping flat metal sheets into desirable forms and sizes, using a series of specialized die presses and stamping techniques. This technique allows for the precise replication of intricate designs, making it a preferred choice for industries such as automotive, aerospace, electronics, and more.One company at the forefront of custom sheet metal stamping is {}. With years of experience in the field, they have mastered the art of transforming raw metal sheets into complex parts that adhere to the highest industry standards. Through their cutting-edge technology and unwavering commitment to quality, they have successfully carved a niche for themselves in this competitive market.The advantages of custom sheet metal stamping are multifold. Firstly, it offers a cost-effective solution compared to traditional fabrication methods such as welding or machining. By avoiding extensive labor and tooling costs, manufacturers can save considerably, which is especially crucial in large-scale production environments.Secondly, custom sheet metal stamping allows for rapid production cycles. The use of advanced die presses and automation enables high-speed production, ensuring timely delivery of finished components. This efficiency not only increases productivity but also enhances overall customer satisfaction.Furthermore, custom sheet metal stamping provides unparalleled design flexibility. Whether it's producing complex shapes or incorporating intricate patterns, manufacturers can easily cater to diverse customer demands. This adaptability is crucial in industries with rapidly changing design trends and aesthetics.In addition to these benefits, custom sheet metal stamping ensures consistency and accuracy across production runs. The use of automated systems minimizes human errors, resulting in consistently high-quality products. This level of precision is important, particularly in safety-critical industries where even the slightest deviation can have severe consequences.Another aspect that sets custom sheet metal stamping apart is its ability to work with a wide range of metals. Whether it's aluminum, stainless steel, copper, or brass, this process can handle various metals with ease, accommodating the specific requirements of different industries and applications.The automotive industry has particularly embraced custom sheet metal stamping due to its exceptional benefits. From body panels to engine components, stamping enables the production of lightweight, yet durable parts. This not only improves fuel efficiency but also enhances vehicle performance and safety.Similarly, the aerospace industry relies heavily on custom sheet metal stamping to fabricate intricate components for aircraft. Stamping technology allows for the production of lightweight yet robust parts, reducing overall weight and increasing fuel efficiency. Moreover, with the ever-increasing demand for aircraft, custom sheet metal stamping enables manufacturers to meet production targets without compromising quality.Custom sheet metal stamping also finds extensive use in the electronics industry. From small components like connectors and terminals to larger parts like enclosures and chassis, this process offers unparalleled precision and quality, ensuring the smooth functioning of electronic devices.In conclusion, custom sheet metal stamping is revolutionizing the manufacturing and fabrication processes across industries. With its cost-effectiveness, rapid production cycles, design flexibility, and high levels of accuracy, this technique provides a competitive edge to manufacturers. Companies like {} are leading the way in producing top-quality stamped metal components, ensuring that customer demands are met efficiently and with utmost precision. As the manufacturing industry continues to evolve, custom sheet metal stamping will undoubtedly play a pivotal role in shaping the future of manufacturing processes.

Read More

Top-quality Lathe Machine Manufacturers in China for Industrial Use

Lathe Machine Supplier - Yangzhou Shinetide Autoparts Manufacture Co., Ltd.When it comes to manufacturing high-quality car parts, it's important to have a reliable supplier that can provide you with the necessary machinery to get the job done. That's where Yangzhou Shinetide Autoparts Manufacture Co., Ltd. comes in. This China-based company specializes in the production of steel bumpers, steel tubular guards, stainless steel tubular guards, and more.At the heart of their production line is their state-of-the-art lathe machining equipment, which allows them to create precision parts with ease. Let's take a closer look at what makes lathe machining such an important process for a company like Yangzhou Shinetide Autoparts.What is Lathe Machining?Lathe machining is a type of manufacturing process that involves using a lathe machine to remove material from a workpiece. This process can be used to create a wide range of parts, including screws, bolts, and even car parts like gears, wheels, and axles.The lathe machine itself consists of a rotating spindle that holds the workpiece in place, and a cutting tool that removes material from the workpiece as it rotates. By adjusting the cutting tool's position and the speed at which the workpiece rotates, machinists can create parts that match the exact specifications required by their clients.Why is Lathe Machining Important for Car Parts?When it comes to creating high-quality car parts, precision is key. Even the smallest imperfection or deviation from the original design can lead to parts that don't fit or function correctly, which can be costly for both the manufacturer and the end consumer.By using lathe machining, companies like Yangzhou Shinetide Autoparts can create parts that are perfectly calibrated to the exact specifications required by their clients. This not only ensures that the parts will fit and function correctly, but also helps to reduce the likelihood of defects or malfunctions down the line.What Sets Yangzhou Shinetide Autoparts Apart?While many companies offer lathe machining services, what sets Yangzhou Shinetide Autoparts apart is their commitment to quality and customer satisfaction.For starters, their lathe machining equipment is top-of-the-line, utilizing the latest technology to create parts with unparalleled precision and accuracy. Additionally, their team of machinists are highly skilled and experienced, and take pride in delivering parts that meet the strictest quality standards.Beyond their machinery and expertise, Yangzhou Shinetide Autoparts also goes above and beyond to ensure that their customers are satisfied with every aspect of their service. From communication and order processing to on-time delivery and after-sales support, they prioritize the customer experience at every stage of the process.ConclusionFor companies looking to manufacture high-quality car parts, having a reliable and skilled lathe machining supplier is essential. Yangzhou Shinetide Autoparts Manufacture Co., Ltd. has established itself as a leader in the industry, offering top-of-the-line equipment and expertise along with a commitment to customer satisfaction.By partnering with a company like Yangzhou Shinetide Autoparts, manufacturers can rest assured that their parts will be precision-engineered to their exact specifications, ensuring a perfect fit and function every time. So if you're in the market for a lathe machining supplier for your car parts manufacturing needs, look no further than Yangzhou Shinetide Autoparts Manufacture Co., Ltd.

Read More

SEO title: "Essential Components of CNC Drilling Machines: A Comprehensive Guide

article about the company's advanced CNC drilling machine parts and their innovative solutions for various industries.{Company Name} is a premier manufacturer and provider of innovative solutions for various industries. With more than 10 years of experience, the company has been dedicated to providing customers with high-quality products, exceptional services, and competitive prices.Their extensive product portfolio includes advanced CNC drilling machine parts, which are engineered to deliver unparalleled accuracy, speed, and flexibility. These parts are designed to be compatible with a wide range of drilling machines, making them an excellent choice for businesses looking to upgrade their drilling equipment.One of the key features of the company's CNC drilling machine parts is their exceptional durability and reliability. Made from the highest quality materials, these parts are designed to withstand the rigors of heavy use in industrial settings. Moreover, they are rigorously tested to ensure they meet or exceed the highest industry standards for quality and performance.At {Company Name}, they understand that each industry has its unique needs and challenges. That's why they offer a range of innovative solutions tailored to meet specific industry requirements. For example, their CNC drilling machine parts are used in the aerospace industry, where precision and accuracy are critical. The parts' high-speed performance and accuracy make them ideal for the production of complex components used by aerospace manufacturers.In the automotive industry, the company's CNC drilling machine parts are used in the manufacturing of critical engine components and other automobile parts. The parts' advanced capabilities make it possible to create intricate shapes and designs with unparalleled speed and accuracy. This, in turn, helps automakers to reduce production costs and improve the quality of their products.In addition to their superior performance capabilities, the company's CNC drilling machine parts are also incredibly easy to use. They feature an innovative design that allows operators to quickly and easily make adjustments to drilling depth and other parameters. This helps to minimize downtime and ensure that drilling operations run smoothly and efficiently.One of the most significant advantages of the company's CNC drilling machine parts is their versatility. Their parts can be used in a range of applications, including drilling, threading, boring, and tapping. This makes them an excellent choice for businesses operating in a variety of industries, from aerospace to automotive, and everything in between.The company's commitment to innovation and customer satisfaction is evident in their dedication to research and development. They are continually working to improve their products, incorporating the latest technologies and materials to offer the best possible solutions to their clients.Overall, {Company Name} is an industry leader in the manufacturing of advanced CNC drilling machine parts. With their exceptional durability, reliability, and versatility, their parts are ideal for businesses looking to upgrade their drilling equipment or improve their production capabilities. So, if you're looking for innovative solutions that can help you take your business to the next level, look no further than {Company Name}.

Read More

Discover High-Quality CNC Turned Parts: Unveiling a Revolutionary News Content!

Title: Innovation in CNC Turned Parts Industry Drives Manufacturing ExcellenceIntroduction:In today's rapidly evolving world, precision engineering plays a crucial role in various industries, from automotive to aerospace. As a leader in the field, {Company Name} has been at the forefront of providing high-quality CNC turned parts that meet diverse market demands. With a strong commitment to innovation and customer satisfaction, they continue to push the boundaries of manufacturing excellence. Let's delve into the details of their recent developments and their impact on the industry.1. Embracing Advanced Technology:{Company Name} has always prioritized investing in cutting-edge technology to improve their product offerings. With a state-of-the-art facility equipped with the latest CNC machining centers and robotic systems, they ensure efficient production processes and enhanced product quality. By utilizing Computer Numerical Control (CNC) machines, these advanced systems enable {Company Name} to manufacture highly precise turned parts with minimal error margins.2. Expanding Capabilities:Recognizing the need to diversify their product portfolio, {Company Name} has recently expanded their capabilities to cater to a broader range of industries. From automotive components to medical devices, their expertise now extends to complex and intricate parts required in various sectors. This strategic expansion has provided customers with a one-stop-shop solution and has strengthened {Company Name}'s position in the market.3. Focus on Quality Control:In an industry where precision is paramount, {Company Name} ensures strict quality control measures at every stage of the production process. By adhering to international standards and implementing stringent inspection protocols, they maintain exceptional quality and minimize defects. Their team of skilled technicians and engineers work meticulously to ensure that each part meets the exact specifications and tolerances set by the customers.4. Streamlined Supply chain:With a strong emphasis on efficiency and timely delivery, {Company Name} has streamlined its supply chain management. This enables them to optimize production, reduce lead times, and minimize costs. By partnering with reliable suppliers, they ensure a seamless flow of materials, further enhancing their responsiveness to customer demands.5. Commitment to Sustainability:As a responsible corporate citizen, {Company Name} remains committed to implementing environmentally friendly practices. They continuously assess their manufacturing processes, seeking opportunities to reduce waste and energy consumption. By adopting sustainable manufacturing techniques and implementing recycling initiatives, they contribute towards a greener future.6. Customer-centric Approach:{Company Name}'s success can be attributed to their strong customer-centric approach. Understanding that each customer has unique requirements, they provide comprehensive solutions tailored to their needs. Whether it's a prototype or high-volume production, their team of experts works closely with customers, providing technical support and guidance throughout the entire manufacturing process.Conclusion:In an industry driven by precision and innovation, {Company Name} has established itself as a reliable supplier of CNC turned parts. Continuously investing in cutting-edge technology, expanding their capabilities, and focusing on quality control, they have earned customer trust and loyalty. With a streamlined supply chain and commitment to sustainable practices, {Company Name} is poised to lead the CNC turned parts industry into an era of manufacturing excellence.

Read More

Modern Parametric Bench: A Fusion of Woodworking Skills and Tools for Building

about the CNC version of the Modern Parametric Bench featured in Popular Woodworking Magazine's December 2019 issue.Title: Small Parts CNC Introduces the Modern Parametric Bench: The Perfect Marriage of Craftsmanship and TechnologyIntroduction: In an exciting collaboration between popular woodworking magazine Popular Woodworking and tech-savvy company Small Parts CNC, woodworking enthusiasts now have the opportunity to build their own version of the Modern Parametric Bench using the power of cutting-edge technology. By combining hybrid woodworking skills with CNC tools, craftspeople can create a stunning, customizable piece of furniture that seamlessly blends craftsmanship with modern design. This exciting project is set to revolutionize the woodworking world, allowing woodworkers to bridge the gap between traditional techniques and contemporary precision.Modern Parametric Bench: The Modern Parametric Bench, a project featured in Popular Woodworking Magazine's December 2019 issue, has gained widespread attention for its sleek design and customizable features. The original project required a combination of traditional woodworking techniques and tools. However, Small Parts CNC has introduced a CNC version of the bench, enabling woodworkers to bring out the full potential of the design while benefiting from the precision and efficiency that CNC technology offers.CNC Technology and Woodworking: CNC (Computer Numerical Control) technology has become increasingly popular in the woodworking industry in recent years. It allows craftspeople to automate the cutting, drilling, and carving processes, resulting in greater accuracy and efficiency. By harnessing the power of CNC tools, woodworkers can achieve intricate and complex designs that would be extremely difficult, if not impossible, to achieve by hand alone. The marriage between traditional woodworking techniques and modern CNC technology represents a significant step forward for the craft, offering both precision and creativity in one seamless package.Small Parts CNC: Small Parts CNC, a pioneering company specializing in CNC technology, has played a pivotal role in integrating CNC technology into woodworking projects. Their expertise and commitment to innovation make them the perfect partner for Popular Woodworking Magazine. With a reputation for exceptional customer service and top-quality products, Small Parts CNC has become a trusted name among woodworking professionals and enthusiasts alike.Building the Modern Parametric Bench: To build the Modern Parametric Bench with CNC technology, woodworkers can use Small Parts CNC's cutting-edge tools such as the [remove brand name], router, and other CNC equipment. The CNC version of the bench project incorporates parametric design principles, allowing users to easily modify and customize the dimensions and patterns to suit their preferences. This level of flexibility opens up endless possibilities for creativity and personalization, ensuring that each finished bench is a unique masterpiece.Advantages of the CNC Version: The CNC version of the Modern Parametric Bench project brings several advantages over the traditional woodworking method. Firstly, the precision and accuracy provided by CNC tools eliminate the risk of human error, resulting in flawless cuts and joints. Secondly, the automation of the carving process enables woodworkers to efficiently reproduce intricate patterns and designs, saving valuable time without compromising on quality. Lastly, the CNC version allows for easy reconfiguration and adjustments, enabling quick modifications to different dimensions or styles according to individual preferences.Conclusion: The collaboration between Popular Woodworking Magazine and Small Parts CNC has brought forth an exciting development in the world of woodworking. The availability of the CNC version of the Modern Parametric Bench project showcases the synergistic combination of craftsmanship and technology. By leveraging the power of CNC tools, woodworking enthusiasts can now create stunning furniture pieces that push the boundaries of creativity and precision. Whether you're an experienced woodworker or a newcomer to the craft, the Modern Parametric Bench with CNC technology offers a thrilling opportunity to merge traditional craftsmanship with cutting-edge innovation.

Read More